17 min read

Internal Control in Mining Contractors

Preventing Fraud Without Slowing Operations For coal mining contractors, internal control is often discussed in uncomfortable terms. It is seen as a...

Logiframe is an Equal Opportunity Employer.

All qualified applicants will receive consideration for employment without regard to race, color, age, religion, sex, sexual orientation, gender identity / expression, national origin, protected veteran status, or any other characteristic protected under federal, state or local law, where applicable, and those with criminal histories will be considered in a manner consistent with applicable state and local laws.

Managed Services

Streamline your finance, tax, and payroll with reliable managed services built for scale.

NetSuite

Unlock enterprise-grade ERP to automate operations, gain insights, and scale your business smarter.

Xero

Empower your growing business with easy, cloud-based accounting and powerful Xero add-ons.

HubSpot

Turn your website, marketing, and CRM into one powerful growth engine with HubSpot solutions built for scale.

Featured Blog

Software akuntansi Xero sudah menggunakan sistem cloud computing yang artinya Anda tidak perlu menginstalnya lagi di PC (Personal Computer). Anda dapat mengakses laporan keuangan perusahaan atau cash flow secara real time asalkan terhubung dengan internet.

By Industries

By Functions

Featured Blog

Dashbor NetSuite adalah salah satu bagian terpenting NetSuite. Memiliki dasbord yang terkonfigurasi dengan benar sangat penting bagi setiap karyawan untuk dapat dengan cepat menavigasi ke data yang mereka perlukan untuk melihat dan mengawasi tren penting.

By Functions

Discover accounting and technology solutions

designed to streamline operations, boost efficiency,

and empower growth for your small business.

Xero Accounting Software

Xero is a cloud-based accounting software that simplifies

invoicing, bank reconciliation, payroll, and expense tracking,

helping businesses manage finances efficiently and in real-time.

Featured Blog

In a remarkable achievement, Xero has been named one of the World’s Top 250 Fintech Companies for 2024 by CNBC. This recognition underscores Xero’s unwavering commitment to innovation, technology, and providing world-class cloud accounting solutions for businesses worldwide.

-1.webp?width=287&height=191&name=Xero%20Recognized%20Among%20the%20Worlds%20Top%20250%20Fintech%20Companies%20in%202024%20(feature%20blog)-1.webp)

Learn about our people, values, and more

About Us Overview →

Our Commitment

Featured Blog

The award underscores Logiframe's position as a trusted partner in leveraging NetSuite solution to drive business success and operational efficiency. This achievement reflects Logiframe's dedication to staying at the forefront of technology and providing outstanding solutions in the dynamic landscape of ERP.

.webp?width=409&height=289&name=Untitled%20design%20(11).webp)

Knowledge

Comparison

Event

Featured Blog

In Cloud ERP for Wholesale and Distribution, NetSuite is the strong Challenger in Gartner's Magic Quadrant for Product-Centric Enterprises. Yes, large ERP vendors dominate the market with Oracle Fusion Cloud ERP, SAP S/4HANA Cloud, and Microsoft Dynamics 365, but NetSuite provides the ideal solution to mid-market wholesale and distribution businesses by delivering robust functionality without excessive costs or complexity.

5 min read

-converted-from-png.webp) Wienanto Tanuwidjaja

:

Jan 16, 2026 4:57:24 PM

Wienanto Tanuwidjaja

:

Jan 16, 2026 4:57:24 PM

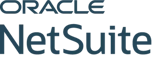

In coal mining contractor businesses, heavy equipment dominates the balance sheet. Excavators, haul trucks, dozers, graders, and support equipment represent enormous capital investment, often financed over many years. As a result, equipment is frequently discussed as an “asset” something to be protected, maintained, and kept running.

This perspective is understandable, but it is also dangerous.

For mining contractors, heavy equipment is not primarily an asset that creates value. It is a cost center that must be continuously justified by productive output. When equipment economics are poorly understood, contractors can appear operationally strong while quietly destroying margins.

This article examines why traditional asset-focused thinking fails in mining contractor businesses, where fleet economics actually break down, how utilization, maintenance, tyres, and spare parts quietly erode profitability, and how disciplined contractors use integrated ERP systems to manage equipment as an economic unit rather than a static asset.

Table of Contents:

1. The Capital-Intensive Reality of Mining Contractors

2. Availability Is Not Utilization

3. Equipment Economics Begin with Utilization Discipline

4. Maintenance Planning: From Preventive to Reactive

5. Tyres: The Blind Spot That Destroys Economics

6. Spare Parts and Inventory Leakage

7. Why Traditional Asset Accounting Falls Short

8. Equipment as an Economic Unit

9. How NetSuite Enables Equipment Cost Discipline

10. Restoring Control Without Disrupting Operations

11. Strategic Implications Beyond Cost Reduction

12. Final Thoughts

Mining contractors operate one of the most capital-intensive business models in any industry. A single large excavator or haul truck can cost millions of dollars. Fleets are financed, depreciated, rebuilt, and replaced over long cycles. Equipment decisions made today can shape cost structures for a decade.

Yet despite this complexity, many organizations manage equipment economics using simplified indicators:

These metrics are operationally useful, but financially incomplete. They answer the question “Is the equipment running?” but not the more important question: “Is the equipment earning its keep?”

One of the most common misconceptions in mining operations is equating availability with productivity.

Availability measures whether equipment is mechanically ready to operate. Utilization measures whether it is actually producing value.

A haul truck can be:

From a financial perspective, availability without utilization is meaningless. Depreciation, financing costs, insurance, and maintenance continue regardless of whether the equipment is productive.

Contractors that focus on availability alone often overstate fleet performance while underestimating cost per BCM.

Utilization determines whether fixed costs are diluted or concentrated.

When utilization is high:

When utilization drops:

The most dangerous scenario is moderate underutilization. It does not trigger alarms, but it steadily inflates unit costs.

Also Read: Broom.id: Transforming Financial Operations with NetSuite

Maintenance is often discussed as a technical discipline. In reality, it is an economic one.

Well-planned preventive maintenance reduces total lifecycle cost by:

Poor maintenance planning shifts the operation into reactive mode:

Reactive maintenance rarely shows up immediately as a crisis. Instead, it manifests as:

Because these effects are distributed across time and equipment units, they are often normalized rather than addressed.

In many mining operations, tyres are one of the largest operating expenses after fuel and maintenance. Yet tyre economics are frequently poorly understood.

Common issues include:

Tyre cost per hour or per BCM can vary dramatically across similar equipment. Without systematic tracking, these variances remain hidden.

When tyre performance is not analyzed at unit level, management cannot distinguish between:

The result is predictable: tyres become an uncontrollable cost.

Spare parts are another area where asset thinking obscures economic reality.

Many contractors carry significant spare parts inventory to ensure uptime. While availability is critical, excess or poorly controlled inventory creates several risks:

When spare parts are issued without being linked clearly to specific equipment units or maintenance activities, cost allocation becomes blurred. Maintenance budgets may appear stable while true equipment economics deteriorate.

From an accounting perspective, heavy equipment is recorded as a fixed asset, depreciated over time, and reported on the balance sheet. This is necessary, but insufficient for management.

Traditional asset accounting:

As a result, management sees depreciation as an inevitable expense rather than a variable that can be optimized through utilization and maintenance discipline.

Also Read: Choosing The Right NetSuite Partner

Equipment as an Economic Unit

Disciplined mining contractors change the framing entirely. They treat each piece of equipment as an economic unit that must justify its existence through output.

This means asking different questions:

To answer these questions consistently, data must be integrated across operations, maintenance, and finance.

NetSuite does not replace fleet management or maintenance execution systems. It provides the financial and analytical layer that connects equipment activity to economic outcomes.

Fixed Asset Management with Economic Context

NetSuite tracks equipment as fixed assets, but crucially links depreciation to:

This allows management to see depreciation not as a static charge, but as a cost that must be recovered through productive use.

Maintenance Cost Tracking by Equipment Unit

Maintenance expenses, including labor, spare parts, and external services, can be assigned directly to individual equipment units.

This creates visibility into:

Management can distinguish between normal wear and economically unjustifiable cost escalation.

Tyre and Spare Parts Cost Attribution

Tyres and critical spare parts can be tracked as components linked to specific equipment units. Their cost and lifespan become measurable.

This enables:

Blind spots disappear when components are treated as economic drivers rather than consumables.

Lifecycle Cost per Unit Analysis

By integrating depreciation, maintenance, fuel, and component costs, NetSuite enables true lifecycle cost analysis.

Management can see:

This supports informed decisions on:

One of the key advantages of treating equipment as a cost center is behavioral clarity.

When supervisors and managers see:

Decisions improve naturally. Conversations shift from blame to economics. Operations and finance align around the same data.

Control improves not through additional bureaucracy, but through transparency.

Proper equipment economics change how contractors compete.

Bids become more accurate because fleet costs are well understood. Contract renegotiations are supported by credible data. Capital investments are timed based on economic performance rather than age alone.

Most importantly, management regains confidence that one of the largest cost drivers in the business is under control.

Heavy equipment is essential to mining contractors, but it is not an asset in the strategic sense. It is a cost center that must earn its place every day.

Contractors that continue to manage fleets based on availability, book value, and intuition will remain vulnerable to silent margin erosion. Those that manage equipment as economic units, supported by integrated systems and disciplined processes, build durable competitive advantage.

By using platforms such as NetSuite to connect asset records, maintenance activity, and financial performance, mining contractors can move from reactive fleet management to proactive economic control.

17 min read

Preventing Fraud Without Slowing Operations For coal mining contractors, internal control is often discussed in uncomfortable terms. It is seen as a...

15 min read

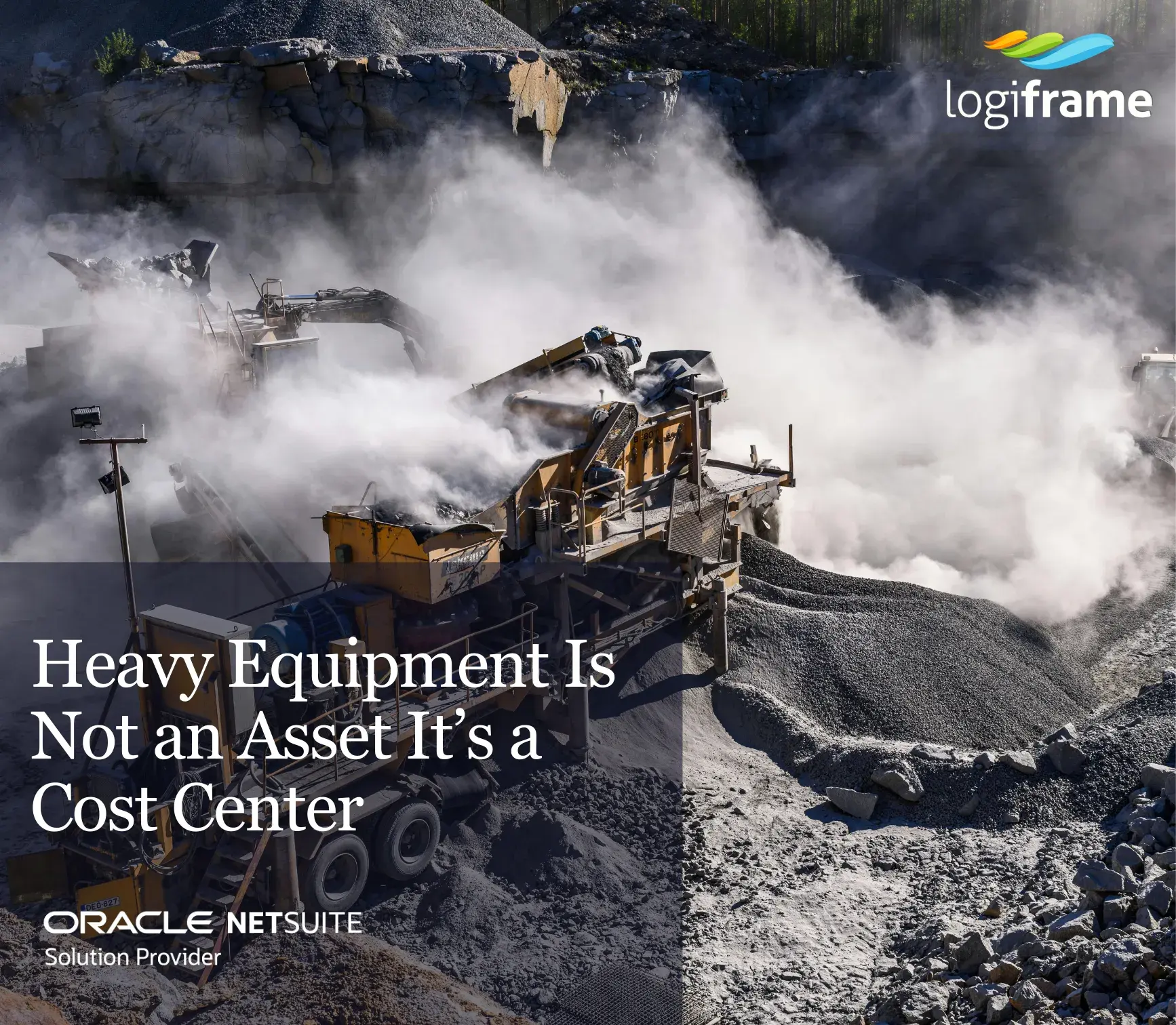

How Mining Contractors Lose Millions Without Knowing It and How Discipline Restores Control For coal mining contractors, fuel is rarely the headline...

13 min read

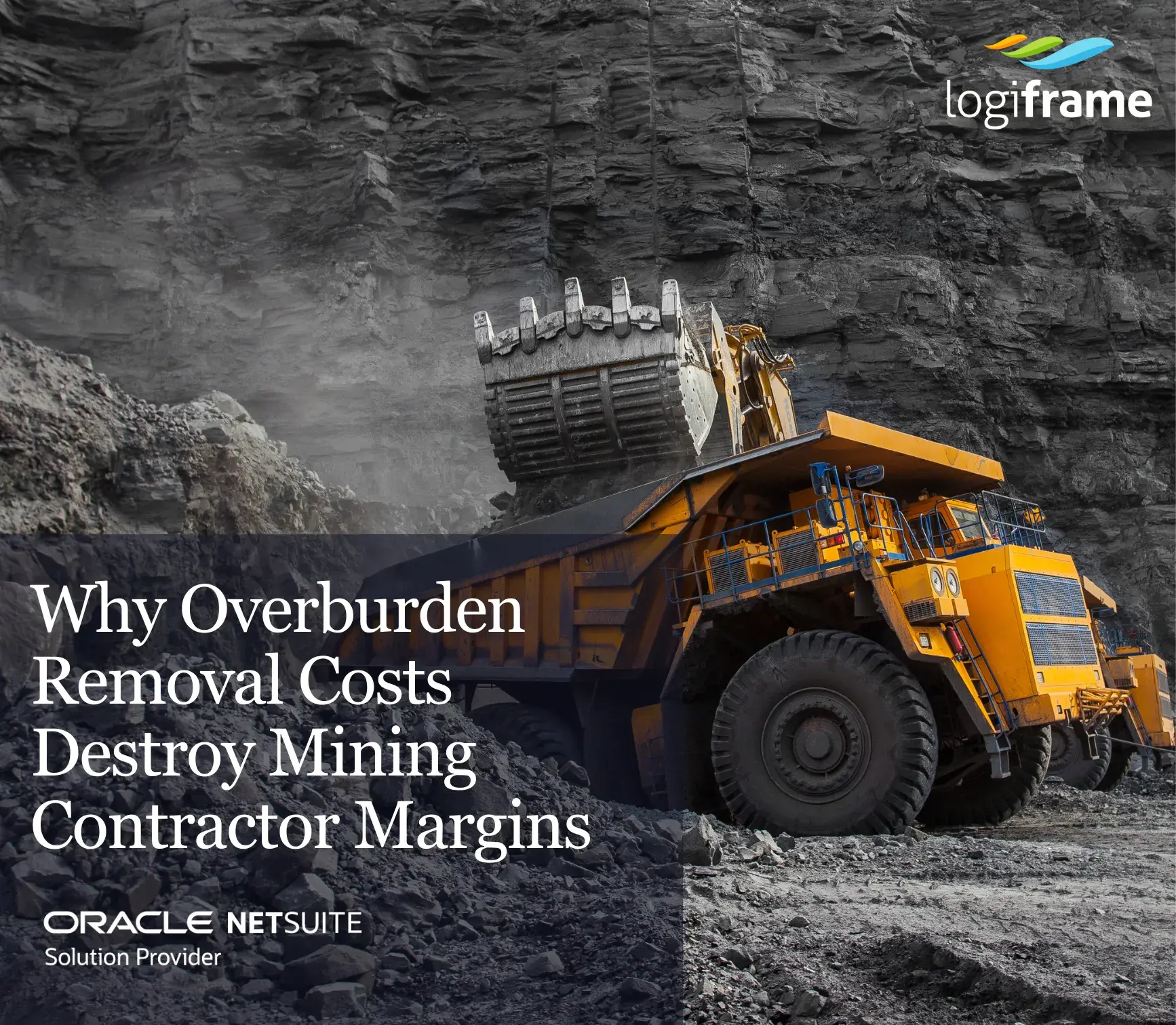

And How Disciplined Contractors Take Back Control For coal mining contractors, overburden removal (OB) is not just one line item among many. It is...